Lian Li PC6070 Quiet Air Intake Project

I've been using a Lian Li PC6070 aluminum computer case for a number of years now for a file server and CAD/CAM workstation and am still satisfied with its performance. It is large enough to house a good number of drives and accessories while providing decent cooling. However, as the inside of the system became hotter and more crowded after numerous upgrades I decided to try to improve the cooling ability while silencing the fans with some of my own modifications.

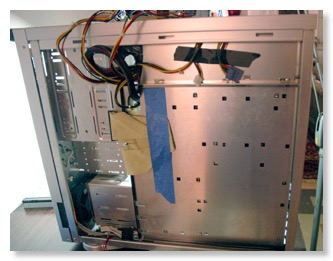

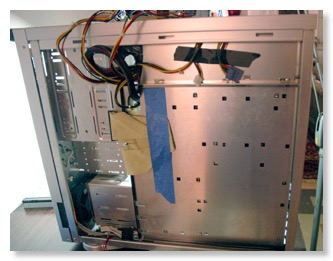

The first change involved cutting another 80mm exhaust fan hole. Lian Li decided to only use one fan for exhaust, even though there was room for two. After some cutting with a jeweler's saw and some cleanup with a metal file I reinstalled the fans. This effectively doubled the exhaust airflow around the CPU area. The hole I created is the lower, rounded rectangle shaped hole (pictured left). I could not use a circular hole pattern because two circular holes would have overlapped and caused a weak point in the aluminum backplane.

The first change involved cutting another 80mm exhaust fan hole. Lian Li decided to only use one fan for exhaust, even though there was room for two. After some cutting with a jeweler's saw and some cleanup with a metal file I reinstalled the fans. This effectively doubled the exhaust airflow around the CPU area. The hole I created is the lower, rounded rectangle shaped hole (pictured left). I could not use a circular hole pattern because two circular holes would have overlapped and caused a weak point in the aluminum backplane.

The next modifications took place about two years later. I wanted to hold on to this case because of it's premium features but felt like the design was showing it's age. For one, cable management was becoming an issue with four hard drives installed. The rounded IDE cable craze had come and gone (mostly due to SATA cables being much thinner) and the motherboard tray design did not allow for any fancy cable routing. There was also an issue with the front intake becoming clogged with dust, since it faced down much like a vacuum cleaner.

So I went back to work, with a cordless drill and the jeweler's saw. I cut a hole in the motherboard tray to allow unused power cables to be routed out of sight, and taped down (shown below).

Next, the IDE ribbon cables received a special dose of cablegami (shown below).

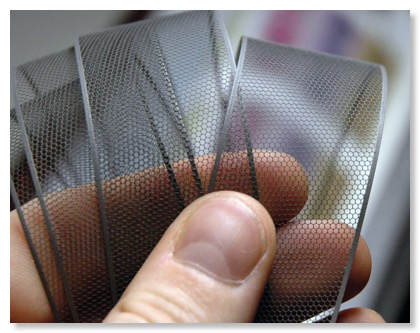

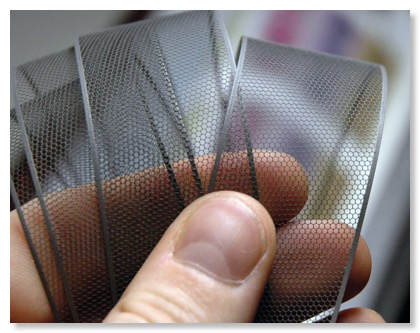

Next, I sealed off the bottom intake holes with cardboard and masking tape, and created new vents in the side of the front bezel. To filter out the dust, metal mesh filters were reused from a Xerox DocuColor laser printer (shown at left).

Next, I sealed off the bottom intake holes with cardboard and masking tape, and created new vents in the side of the front bezel. To filter out the dust, metal mesh filters were reused from a Xerox DocuColor laser printer (shown at left).

I've recently replaced all the original 80mm case fans in addition to the 120mm PSU fan. I guess they lasted as long as they should have considering they spun 24 hours a day for almost 5 years. The new fans are low noise, rubber dampened units from Silverstone and Scythe, respectively. Since these fans spin at a low RPM, I needed to increase the intake surface somewhat to compensate for the lower pressurization. I decided to use the three 3.5" drive bay covers since I could fit an 80mm fan directly behind them, and directly in front of the two Samsung Spinpoint hard drives currently in the system. I again used the Xerox toner screens for dust filtration.

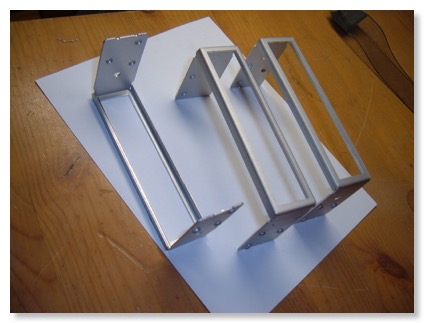

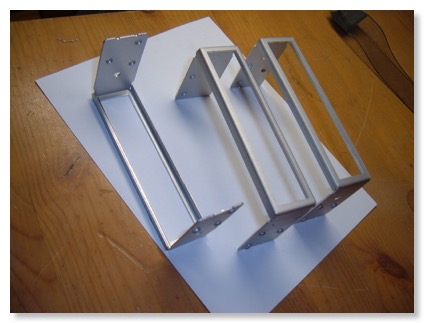

The three bay covers after I sawed a large rectangle out of each of their faces (below).

View of the 80mm fan, for hard drive air intake (below).

Detail of the discarded Xerox toner filters to be reused as intake filters (below).

Here is the finished drive bay intake (at left) with the filters in place. They pop out easily and can be cleaned by running them under water or using compressed air.

Here is the finished drive bay intake (at left) with the filters in place. They pop out easily and can be cleaned by running them under water or using compressed air.

Despite having quieter, lower RPM fans, the result was increased cooling capacity and overall lower noise. Not pictured are other sound deadening enhancements like electrical tape and rubber grommets on metal mating surfaces (especially the hard drive cage and mounts) to reduce vibration.

The next modifications took place about two years later. I wanted to hold on to this case because of it's premium features but felt like the design was showing it's age. For one, cable management was becoming an issue with four hard drives installed. The rounded IDE cable craze had come and gone (mostly due to SATA cables being much thinner) and the motherboard tray design did not allow for any fancy cable routing. There was also an issue with the front intake becoming clogged with dust, since it faced down much like a vacuum cleaner.

So I went back to work, with a cordless drill and the jeweler's saw. I cut a hole in the motherboard tray to allow unused power cables to be routed out of sight, and taped down (shown below).

Next, the IDE ribbon cables received a special dose of cablegami (shown below).

I've recently replaced all the original 80mm case fans in addition to the 120mm PSU fan. I guess they lasted as long as they should have considering they spun 24 hours a day for almost 5 years. The new fans are low noise, rubber dampened units from Silverstone and Scythe, respectively. Since these fans spin at a low RPM, I needed to increase the intake surface somewhat to compensate for the lower pressurization. I decided to use the three 3.5" drive bay covers since I could fit an 80mm fan directly behind them, and directly in front of the two Samsung Spinpoint hard drives currently in the system. I again used the Xerox toner screens for dust filtration.

The three bay covers after I sawed a large rectangle out of each of their faces (below).

View of the 80mm fan, for hard drive air intake (below).

Detail of the discarded Xerox toner filters to be reused as intake filters (below).

Despite having quieter, lower RPM fans, the result was increased cooling capacity and overall lower noise. Not pictured are other sound deadening enhancements like electrical tape and rubber grommets on metal mating surfaces (especially the hard drive cage and mounts) to reduce vibration.